What Is the Cosmetic Industry? Complete Overview from Manufacturing to Packaging and Dispatch

Introduction

The cosmetic industry covers everything from product concept creation to final dispatch of finished cosmetic products. It is not limited to mixing ingredients only. A professional cosmetic product goes through multiple controlled stages such as formulation, manufacturing, quality control, packaging, storage, and dispatch.

This article explains the complete cosmetic industry workflow, starting from manufacturing and ending at dispatch, in a simple and professional way.

What Is the Cosmetic Industry?

The cosmetic industry includes companies and manufacturers involved in:

- Developing cosmetic formulations

- Manufacturing cosmetic products

- Packaging and labeling

- Storing and dispatching finished goods

Cosmetic products are designed for external use only and focus on cleansing, protecting, beautifying, or improving appearance.

Major Segments of the Cosmetic Industry

- Skincare products

- Haircare products

- Personal hygiene products

- Color cosmetics

Each segment follows a similar manufacturing-to-dispatch workflow, with minor technical differences.

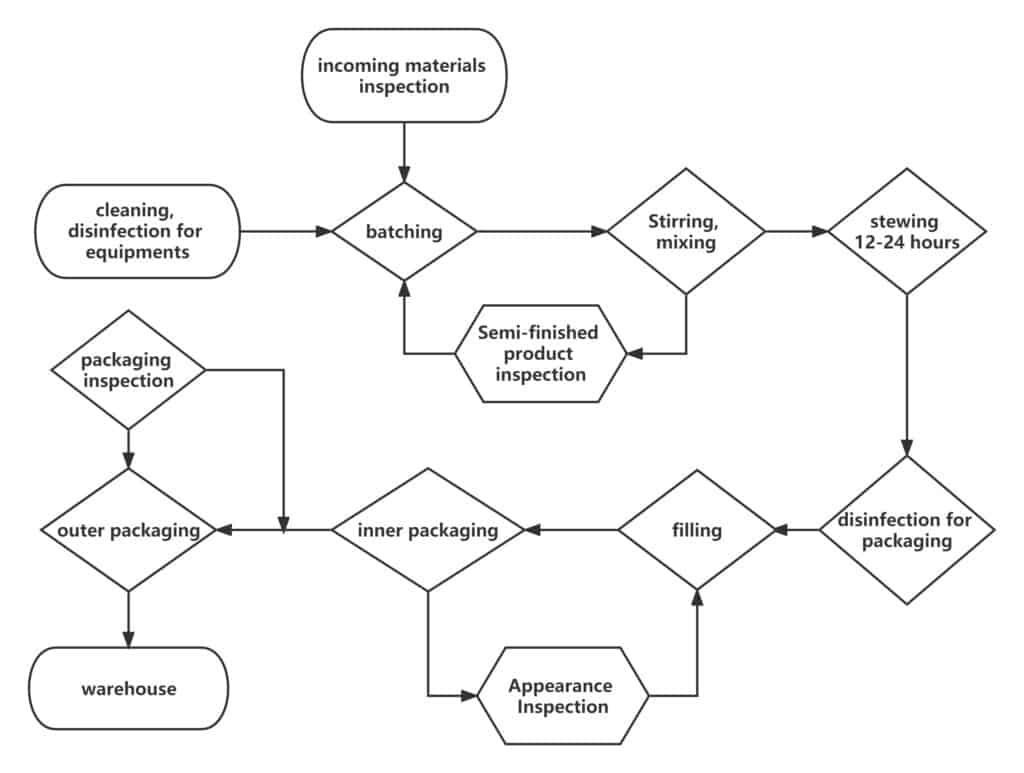

Complete Cosmetic Manufacturing Process (Step-by-Step)

Step 1: Product Planning & Concept Development

Before manufacturing starts, planning is done for:

- Product type (cream, lotion, shampoo, serum, soap)

- Target users (men, women, baby, sensitive skin)

- Claims (herbal, sulfate-free, paraben-free)

- Texture, fragrance, and color preference

This stage decides commercial success or failure of the product.

Step 2: Raw Material Procurement & Approval

Only approved cosmetic-grade raw materials are selected, such as:

- Oils and butters

- Water-phase ingredients

- Emulsifiers

- Thickeners

- Preservatives

- Fragrances and colors

Each raw material is checked for:

- Certificate of Analysis (COA)

- Safety data

- Compatibility

Step 3: Cosmetic Formulation Development

Formulation is the backbone of cosmetic manufacturing and includes:

- Percentage calculation of ingredients

- Oil phase and water phase separation

- pH range selection

- Stability planning

Without a proper formulation, no cosmetic product can survive in the market.

Step 4: Manufacturing Process (Production Stage)

4.1 Preparation of Water Phase

Water-soluble ingredients are added

Heated to required temperature (usually 70–75°C)

4.2 Preparation of Oil Phase

Oils, waxes, emulsifiers are melted

Heated to the same temperature as water phase

4.3 Emulsification

Oil phase is slowly added to water phase

Mixing is done using a homogenizer or stirrer

4.4 Cooling Phase

- Batch is cooled gradually

- Heat-sensitive ingredients are added below 40°C

This step ensures stable and smooth texture.

Step 5: Quality Control (QC) & In-Process Testing

Quality control is mandatory at every stage.

Key Tests Include:

- pH testing

- Viscosity check

- Color and odor check

- Appearance and texture

- Microbial safety (if applicable)

❗ Without QC, products may fail in the market or get customer complaints.

Step 6: Filling Process (Bulk to Pack Conversion)

After QC approval, the product moves to filling.

Filling Includes:

- Selecting suitable containers (jar, bottle, tube)

- Using filling machines or manual filling

- Weight and volume accuracy check

- Leakage testing

This stage converts bulk product into saleable units.

Step 7: Packaging & Labeling

Packaging protects the product and provides legal information.

Primary Packaging

- Container holding the product (jar, bottle, tube)

Secondary Packaging

- Outer box or shrink wrap

Label Must Contain:

- Product name

- Ingredient list (INCI names)

- Batch number

- Manufacturing & expiry date

- Usage instructions

Incorrect labeling can lead to legal issues.

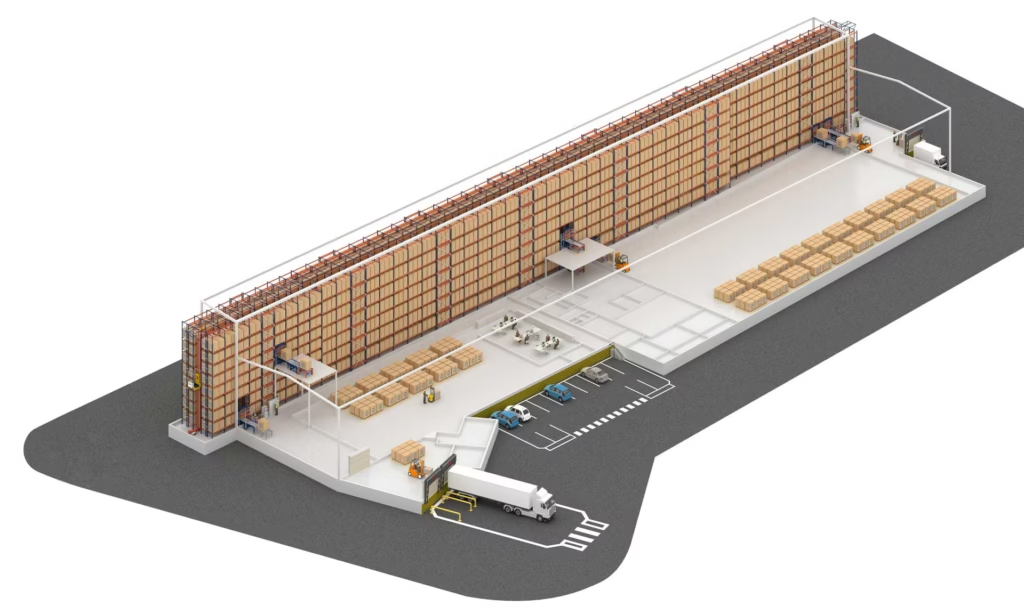

Step 8: Finished Goods Storage

After packaging, products are stored in controlled conditions.

Storage Guidelines:

- Clean and dry warehouse

- Controlled temperature

- FIFO system (First In, First Out)

- Batch-wise stacking

Improper storage can reduce shelf life.

Step 9: Dispatch & Logistics (Final Step)

Dispatch is the final stage of the cosmetic industry workflow.

Dispatch Process Includes:

- Order verification

- Invoice and documentation

- Secondary protective packing

- Transport mode selection (road, courier, freight)

Important Dispatch Points:

- Product safety during transport

- Avoid heat and leakage

- Proper carton labeling

- Tracking and delivery confirmation

Efficient dispatch ensures customer satisfaction and brand trust.

Why Manufacturing-to-Dispatch Control Is Important?

Complete control from manufacturing to dispatch ensures:

- Consistent product quality

- Reduced returns and complaints

- Legal compliance

- Strong brand reputation

Cosmetic Industry vs Random Homemade Products

| rofessional Cosmetic Industry | Homemade Mixing |

|---|

| Scientific formulation | No formulation |

| Quality control | No testing |

| Legal compliance | High risk |

| Shelf life stability | Unstable |

Conclusion

The cosmetic industry is a system-driven industry, not a random mixing process. From formulation and manufacturing to packaging, storage, and dispatch, every step must be properly controlled.

Understanding this complete workflow is essential for anyone planning to enter cosmetic manufacturing or private label business.