Quality Assurance Pharma 2025

Quality Assurance In the pharmaceutical industry, where human health and safety are top priorities

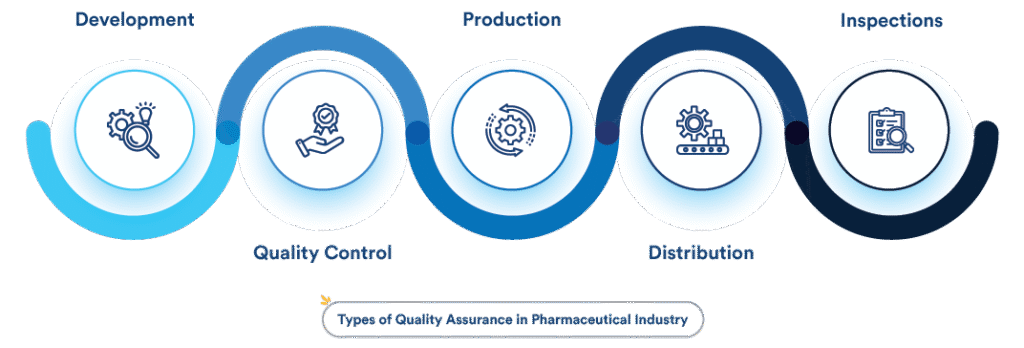

Quality Assurance (QA) plays a critical role in ensuring that medicines are safe, effective, and meet regulatory standards. QA is not just a department—it’s a philosophy and a systematic process that governs how pharmaceutical products are manufactured, tested, stored, and delivered.

This blog will provide a complete overview of the QA department in the pharmaceutical industry, including its roles, responsibilities, importance, and impact on regulatory compliance.

🔍 What is Quality Assurance (QA) in Pharma?

Quality Assurance in the pharmaceutical industry refers to a wide range of planned and systematic actions implemented within the quality system to ensure that a product meets the required quality standards.

Unlike Quality Control (QC)—which is about testing the final product—QA focuses on preventing errors throughout the manufacturing and development process by building quality into the system from the start.

🧩 Structure of QA Department

The QA department in a pharmaceutical company usually comprises several key subdivisions:

Documentation Team

Validation & Qualification Team

Auditing & Compliance Team

Training & SOP Monitoring

Change Control & Deviation Handling Team

Each of these plays a vital role in maintaining Good Manufacturing Practices (GMP) and other quality standards.

🎯 Key Responsibilities of the QA Department

1. Development and Management of SOPs

Standard Operating Procedures (SOPs) are critical in the pharma industry. QA ensures:

SOPs are written clearly and in compliance with regulations.

Regular review and version control of SOPs.

Training staff on relevant SOPs.

2. Batch Record Review

QA is responsible for reviewing:

Batch Manufacturing Records (BMRs)

Batch Packaging Records (BPRs)

This ensures that every batch of medicine is traceable and manufactured correctly.

3. Deviation Management

Whenever a process deviates from the defined SOPs or batch records, QA must:

Investigate the deviation.

Identify root causes.

Implement corrective and preventive actions (CAPA).

4. Change Control

If a change in equipment, materials, or processes is necessary, QA ensures:

Proper documentation and approval.

Risk assessment and validation before implementation.

5. Training Programs

QA conducts and tracks employee training to ensure that:

Staff is competent in GMP and job functions.

Training records are up to date.

6. Self-Inspections and Audits

QA plans and executes:

Internal audits

Supplier audits

Third-party inspections

Findings are documented and followed up with CAPAs.

7. Validation and Qualification

QA is responsible for:

Process Validation

Equipment Qualification

Cleaning Validation

These activities ensure consistent and reliable output.

8. Regulatory Compliance

QA ensures compliance with:

WHO-GMP

USFDA

MHRA

EMA

CDSCO

QA prepares the company for inspections and maintains readiness for audits.

9. Quality Risk Management

QA assesses the risks associated with each process and implements control strategies to minimize them.

📜 Importance of QA in the Pharmaceutical Industry

Patient Safety

Medicines must be free from contamination and must contain the correct strength. QA ensures this through robust systems.Regulatory Compliance

A strong QA system avoids legal issues and regulatory penalties.Market Authorization and Product Approval

Drugs must meet stringent quality guidelines to be approved by global agencies. QA supports dossier preparation and technical files.Brand Reputation

A poor-quality product can damage a company’s image. QA ensures consistent product quality.Cost Efficiency

By preventing errors rather than correcting them later, QA saves time and money.

🏢 Common Roles in QA Department

| Role | Responsibility |

|---|---|

| QA Executive | Daily document review, deviation handling |

| QA Officer | SOP preparation, batch record review |

| QA Manager | Overall supervision, audit readiness |

| QA Auditor | Conduct internal/external audits |

| Validation Engineer (QA) | Oversee validation and qualification activities |

| Aspect | QA (Quality Assurance) | QC (Quality Control) |

|---|---|---|

| Focus | Process-oriented | Product-oriented |

| Approach | Preventive | Corrective |

| Responsibility | Entire production lifecycle | Final product testing |

| Activities | SOPs, audits, training, validation | Sampling, lab testing, reporting |

📅 Day-to-Day Activities of QA Department

Morning review meetings

Cross-checking BMRs and BPRs

Monitoring cleanroom environment data

Validating new cleaning methods or processes

Preparing for audits

CAPA follow-up and documentation

Ensuring online documentation at every step

🌍 Global Standards QA Adheres To

ICH Guidelines

21 CFR Part 11 (USFDA)

WHO GMP

PIC/S

EU GMP Annexures

QA ensures the company’s systems align with international quality and safety standards.

🧠 Skills Required for QA Professionals

Attention to detail

Regulatory knowledge

Communication and documentation

Problem-solving ability

Audit preparedness

Strong understanding of manufacturing processes

📈 Challenges Faced by QA Teams

Keeping up with regulatory updates

Managing large volumes of documentation

Ensuring consistent training across departments

Root cause analysis for recurring deviations

Digital transformation and compliance with e-record systems

✅ Future of QA in Pharma

The future of QA is becoming more digitized and data-driven:

Use of AI for quality trend analysis

Digital QMS (Quality Management Systems)

Real-time batch record reviews

Focus on data integrity and cybersecurity

📌 Conclusion

The QA department is the backbone of the pharmaceutical industry, ensuring that every drug manufactured is safe, effective, and meets global standards. From managing SOPs to conducting audits and training employees, QA is deeply involved at every stage of drug development and manufacturing.

Pharmaceutical companies that invest in a robust QA system are more likely to build trust, avoid recalls, pass regulatory audits, and maintain a competitive edge in the global market.